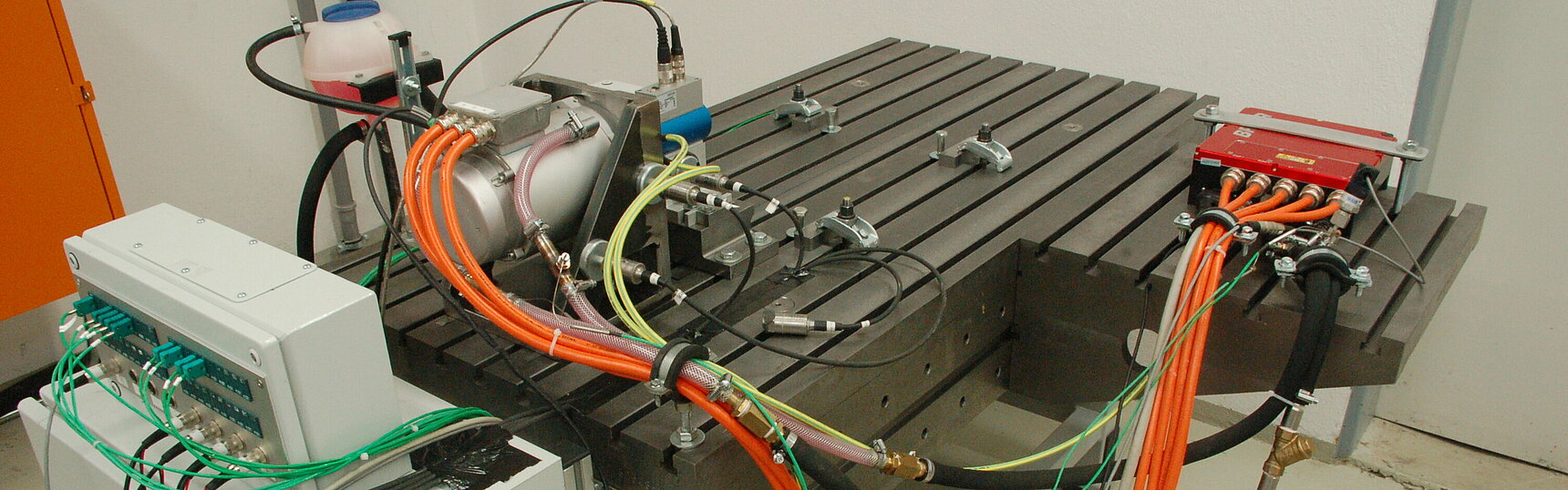

Development Test Bench for High-Speed Drives

The test bench enables the testing of eDrives in very early stage of development. For this it provides high speed up to 24.000 rpm but low torque. Typical applications are highly precise drag torque measurements and thermal examinations under the influence of rotational speed. In order to achieve the maximum possible flexibility during testing, the test bench has a modular and flexible design. A comprehensive range of test bench equipment is available for operating and analysing modern drivetrains.

Download the flyer

Contact

Ph.: +49 711 685-65662

Range of Services

- Initial commissioning

- Efficiency measurements (mechanical and electrical) and highly precise drag torque measurements

- Testing of durability, application and function

- Investigation of dynamic behavior as well as thermal and vibrational effects

- Hardware-in-the-loop testing

- Wide range of special tests

We are happy to take on the design, construction and production of individual test item adaptations.

Technical Data

Input eDrive |

|

| Power, max. | 157 kW |

| Torque, max. | 300 Nm |

| Speed, max. | 13.000 1/min |

Alternative input eDrive | |

| Power, max. | 35 kW |

| Torque, max. | 14 Nm |

| Speed, max. | 24.000 1/min |

Battery simulator | |

| Power, max. | 1.160 kW |

| Voltage range | 0...1.000 V |

| Current, max. | 1.600 A |

| Dynamic | 2.000 V/ms |

Test Bench Equipment

- Hardware-in-the-loop simulation environment

- Common tools for remaining bus simulation, diagnosis and application

- A comprehensive range of measurement technology (mechanical, electrical including high-voltage, hydraulic, thermal)

- Conditioning and media supply

- Sensor for highly precise drag torque measurement

- High-resolution vibration measurement technology

- Early damage detection system

- Operational balancing device