Heat Balance Test Bench

A test bench was equipped with the necessary peripherals for the thermal balancing of engines. These are essentially aggregates which condition the individual media with high precision, as well as special temperature measurement technology.

It is characterized by the following properties:

- Setting the temperatures of coolant, charge air, engine oil, fuel and intake air using high-precision controlled conditioning systems

- Determining the heat flows in liquid media using internally developed heat flow measurement units (HMU) that are applied between engine and conditioning system

- Determining the exhaust-gas temperature using so-called thermal combs

- Determining the heat radiation using special surface thermocouples

- Possibility for varying the flow rate of the coolant

Contact

Ph.: +49 711 685-68091

Technical Data

| Test bench | Pmax | Mmax | nmax | Remarks |

[kW] | [Nm] | [min -1] | Options | |

| Heat balance test bench | 470 | 990 | 9.000 | |

| Heat balance test bench | 350 | 1.000 | 9.000 | CNG |

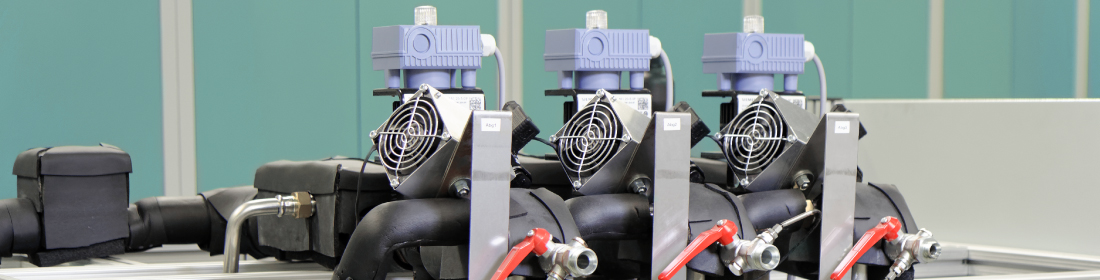

Heat Flow Measurement Units

The heat flow measurement units (HMU) developed by the FKFS for the heat balancing of engines are used for measuring heat flows in liquid media.

A temperature measuring pocket is located at the HMU input (engine outlet). The medium to be measured continues to flow into a conditioning system. After conditioning, the mass flow is measured in the HMU. A temperature measuring pocket is located again at the HMU output (engine inlet).

Each of the temperature measuring pockets features seven thermocouples. One of them measures the absolute temperature. The remaining six thermocouples of the inlet temperature measuring pockets is connected with the six thermocouples of the outlet temperature measuring pocket in such a way that six times the temperature difference is measured.

The setup described applies to the intercooler coolant HMU. The engine coolant HMU also features a booster pump. In an oil HMU, the oil is not fed to a conditioning system, but simply fed through an oil-water heat exchanger whose secondary side can accept a water conditioning system.